Plant Design Support

Designing a plant expansion or full greenfield development is a serious undertaking involving not just engineers but business and financial stakeholders throughout the company. It needs to be approached correctly and with success in mind.

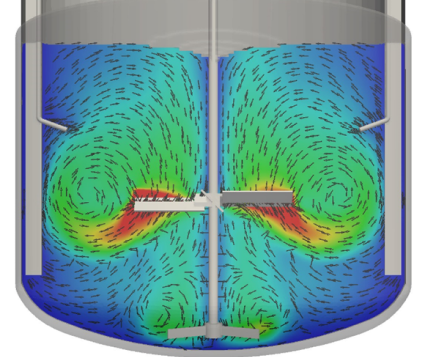

Myant X is able to drive the process and collaborate directly with EPC firms to properly inform the decision-making process. Whether it’s small decisions that could have a big-impact, like valve-sizing for heterogeneous systems or large decisions like which technology to use for a critical filtration operation – Myant X can help inform, test, and validate. Leveraging our unique experience in novel processing technologies, we have not just the capability but the experience to help de-risk any plant design project from start-to-finish.

Process Data Generation

Before a product is launched, the most valuable contribution from the RD&E team(s) is data, not materials alone. It’s the results of modeling, simulation, and experimentation that facilitate data-based decision making and enable process design de-risking.

Our labs and pilot plant are equipped with a wide range of capabilities and infrastructure, allowing us to actually test ideas and assumptions prior to signing-off on any large capital projects. One of the primary data inputs needed at early stages in design is calorimetry. Understanding whether energy goes during the process is critical to enabling efficient design but most importantly a safe design. The energy flow also informs the techno-economics of the process as well as any potential life-cycle assessments.

Technology Transfer

At Myant X, success is all about the hand-off and moving our projects from RD&E to manufacturing.

The majority of processes we touch require economies of scale to be competitive and we enable this by leveraging our network of contract manufacturer organizations (CMO). Unlike most engagements with CMOs, you own the process from start to finish, we do not hold process operating instructions back to land production deals. The benefit to this approach is that a fully de-risked process presents a far greater opportunity to engage with CMOs as both parties know what they are getting into right away.