Testing, Evaluation, & Quality Control

Performance testing that connects characterization of basic material properties with integrated device and subsystem functional requirements to assist the development of new products.

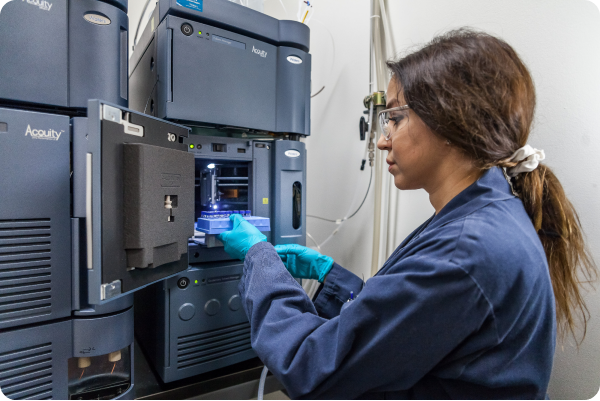

Separation Chromatography

•HPLC (RI & PDA detectors)

•UPLC (PDA & MS/MS detectors)

•GPC, APC (RI detector)

•GC-FID, Headspace-GC-FID (TCD & MS detectors)

•Ion Chromatography

•Preparatory HPLC-PDA & GPC-RI

Spectroscopy

•UV-Vis Spectrometer

•FT-IR Spectrometer

•Fluorescence Spectrometer

•Tintometer for Color Analysis

•NMR (400 MHz, 1H, 13C, 15N, 19F, 31P)

•Colorimetric Analysis

Microscopy

•Optical Microscopy (digital with 3D imaging & variable temperature capabilities

•SEM, SEM-EDS

•TEM (with staining)

Elemental Analysis

•ICP-OES

•CHN (LECO 628 System)

•Oxygen Determination (LECO VTF-900)

•Sulphur Analyzer (LECO S-932)

Particle Analysis

•Nanotrac 252 Particle Size Analyzer

•SYSMEX 3000 FPIA (Particle size and shape)

•Beckman Coulter Multisizer 3

•Malvern Nanosizer

•Malvern Zetasizer (Zeta potential)

•Powder X-Ray Diffraction (XRD)

•Surface Area Analysis (BET)

Mechanical Characterization

•DMA (Q800)

•Rheology

-High-temp, strain controlled (Ares G2 & RFS3)

-Medium to high viscosity materials (DHR-2)

•Hardness (Durometer)

•Abrasion/rub

-Sutherland tester

-linear/rotary taber abraders

-RT4 rotary abrader)

•Friction and wear

-Pin-on-disk

-Linear reciprocating tribometer

•Thermal diffusivity and conductivity of films (Nanoflash)

•Thermal conductivity of solids (C-Therm)

•Impact testing (Tinius Olsen)

•Instron 3367 mechanical testing

-temperature-controlled stress, strain, creep, stress relaxation, peel, and delamination

Electrical Characterization

•Cyclic Voltammetry

•Photocurrent time-of-flight charge transport

•Current/voltage measurement

-Temperature and humidity-controlled environments

•Magnetic remanence and susceptibility (fixed field)

•Static charge decay

-JCI155 corona charge decay analyser

•Transistor characterization (Keithly 4200)

•Semiconductor evaluation

-Top contact, bottom contact device preparation

-Mobility, on-off voltage measurements

•Resistivity/conductivity – surface and volume

¡Keithley 65174 4 probe & 2 probe

Thermal Analysis

•Differential Scanning Calorimeter (DSC)

•Modulated Differential Scanning Calorimeter (MDSC)

•Thermogravimetric Analysis (TGA)

•Melt Flow Index (MFI)

•Rheology (temperature & frequency sweep)

•Brookfield Viscometer

•Reaction Calorimetry (RC)

Surface Film Characterization

•Surface tension (Tensiometer K100)

•Surface profilometry

-Nanovea optical profiler

-Dektek 6 contact profilometer

•Contact angle

-temperature-controlled static, dynamic, and sliding angles (FibroDAT and FTA200)

•Film thickness

-contact/non-contact (Metricon)

•Co-efficient of friction (TMI Slip and Friction)

•Surface roughness

-L&W Sheffield tester

-Toyo-Seiki Microtopograph dynamic roughness

tester

•Porosity, Pore Size Distribution

-L&W permeance tester

-Coulter porometer

•Tensile and Modulus

-TMI ZDT tensile tester

-SST250 ultrasonic modulus tester

Titration Units

•Karl Fischer

•Potentiometric Titrations (pH, amine, acid numbers)

•Conductometric Titrations